With our outstanding management, robust technical capability and strict top quality regulate system, we carry on to supply our shoppers with reputable top quality, reasonable charges and excellent companies. We purpose at becoming amongst your most reliable partners and earning your fulfillment for Elastomer bellow mechanical seal replacement type 560, Our ultimate objective is always to rank as a top brand also to lead as a pioneer inside our field. We’re sure our prosperous experience in tool generation will gain customer’s trust, Wish to co-operate and co-create an even better upcoming with you!

With our outstanding management, robust technical capability and strict top quality regulate system, we carry on to supply our shoppers with reputable top quality, reasonable charges and excellent companies. We purpose at becoming amongst your most reliable partners and earning your fulfillment for Elastomer Bellow Mechanical Seal, Pump Mechanical Seal, single spring pump seal, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

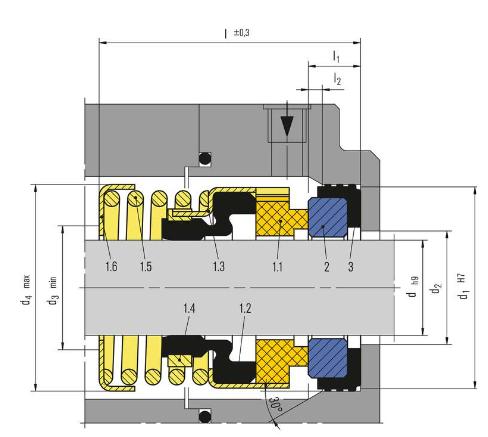

Features

•Single seal

•Loosely inserted seal face provides self-adjusting capability

•In-house manufactured sliding parts

Advantages

The W560 is self-adjusting to shaft misalignments and deflections because of the loosely inserted seal face as well as the ability of the bellows to stretch and tighten. The length of the contact area of the bellows with the shaft is an optimum compromise between ease of assembly (less friction) and sufficient adhesive force for torque transmission. Additionally, the seal fulfills very specific leakage requirements. Because the sliding parts are made in-house, a wide variety of special needs can be accommodated.

Recommended applications

•Water and waste water technology

•Chemical industry

•Process industry

•Water and waste water

•Glycols

•Oils

•ndustrial pumps/equipment

•Submersible pumps

•Engine pumps

•Circulating pumps

Operating range

Shaft diameter:

d1 = 8 … 50 mm (0.375″ … 2″)

Pressure:

p1 = 7 bar (102 PSI),

vacuum … 0.1 bar (1.45 PSI)

Temperature:

t = -20 °C … +100 °C (-4 °F … +212 °F)

Sliding velocity: vg = 5 m/s (16 ft/s)

Axial movement: ±1.0 mm

Combination materials

Stationary Ring (Ceramic/SIC/TC)

Rotary Ring (Plastic Carbon/Carbon/SIC/TC)

Secondary Seal (NBR/EPDM/VITON)

Spring & Other Part s(SUS304/SUS316)

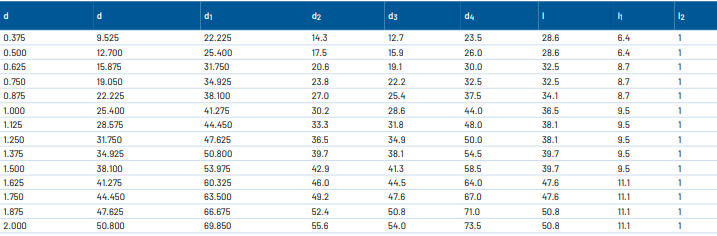

W560 data sheet of dimension (inches)

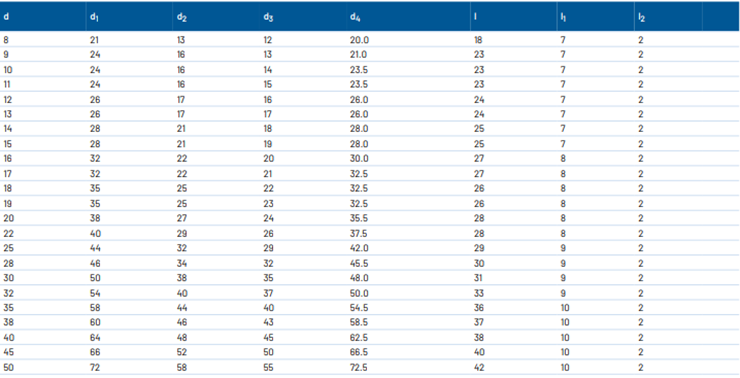

W560 data sheet of dimension (mm)

Our advantages

Customization

We have a strong R&D team, and we can develop and produce products according to the drawings or samples the customers offered,

Low Cost

We are production factory, compared with the trading company, we has great advantages

High Quality

Strict material control and perfect testing equipment to ensure product quality

Multiformity

Products include slurry pump mechanical seal, agitator mechanical seal, paper industry mechanical seal, dyeing machine mechanical seal etc.

Good Service

We focus on developing high-quality products for top-end markets. Our products are in line with international standards

Application

Our products are successfully used in different fields, such as Water treatment, Petroleum, Chemistry, refinery, pulp & paper, food, marine etc.we can produce mechanical seal for bellow mechanical seal spring