“Quality initial, Honesty as base, Sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for M7N pump mechanical seal for marine industry, And we can help wanting for virtually any products on the customers’ needs. Make sure present the most beneficial Assistance, the ideal Good quality, The quick Delivery.

“Quality initial, Honesty as base, Sincere assistance and mutual profit” is our idea, as a way to produce continuously and pursue the excellence for m7n PUMP SEAL, Pump And Seal, Pump Shaft Seal, Water Pump Shaft Seal, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We’re looking forward to establish business relation with you.

Replacement for the below mechanical seals

Burgmann M7N ,LIDERING LWS10, Latty U68, Flowserve Europac 600, Vulcan 1677, AESSEAL W07DMU, Anga V, Sterling 270, Hermetica M251.K2

Features

- For plain shafts

- Single seal

- Unbalanced

- Super-Sinus-spring or multiple springs rotating

- Independent of direction of rotation

Advantages

- Universal application opportunities

- Efficient stock keeping due to easily interchangeable faces

- Extended selection of materials

- Insensitive to low solids contents

- Flexibility in torque transmissions

- Self-cleaning effect

- Short installation length possible (G16)

- Pumping screw for media with higher viscosity

Operating Range

Shaft diameter:

d1 = 14 … 100 mm (0.55 ” … 3.94 “)

Pressure:

p1 = 25 bar (363 PSI)

Temperature:

t = -50 °C … +220 °C

(-58 °F … +428 °F)

Sliding velocity:

vg = 20 m/s (66 ft/s)

Axial movement:

d1 = up to 25 mm: ±1.0 mm

d1 = 28 up to 63 mm: ±1.5 mm

d1 = from 65 mm: ±2.0 mm

Combination Material

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Cr-Ni-Mo Steel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Rubber(MVQ)

PTFE Coated VITON

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Recommended Applications

- Process industry

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Shipbuilding

- Lube oils

- Low solids content media

- Water / sewage water pumps

- Chemical standard pumps

- Vertical screw pumps

- Gear wheel feed pumps

- Multistage pumps (drive side)

- Circulation of printing colors with viscosity 500 … 15,000 mm2/s.

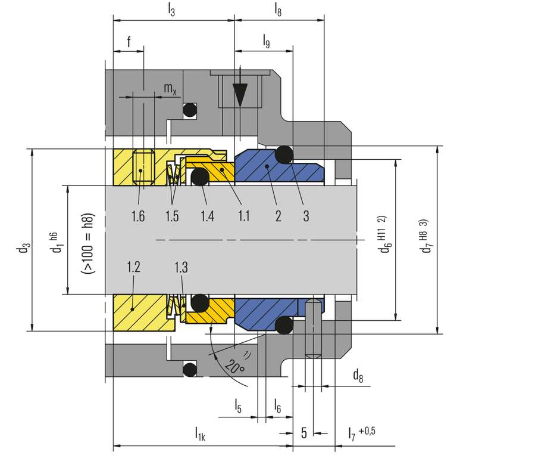

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 412.1 O-Ring

1.3 474 Thrust ring

1.4 478 Righthand spring

1.4 479 Lefthand spring

2 475 Seat (G9)

3 412.2 O-Ring

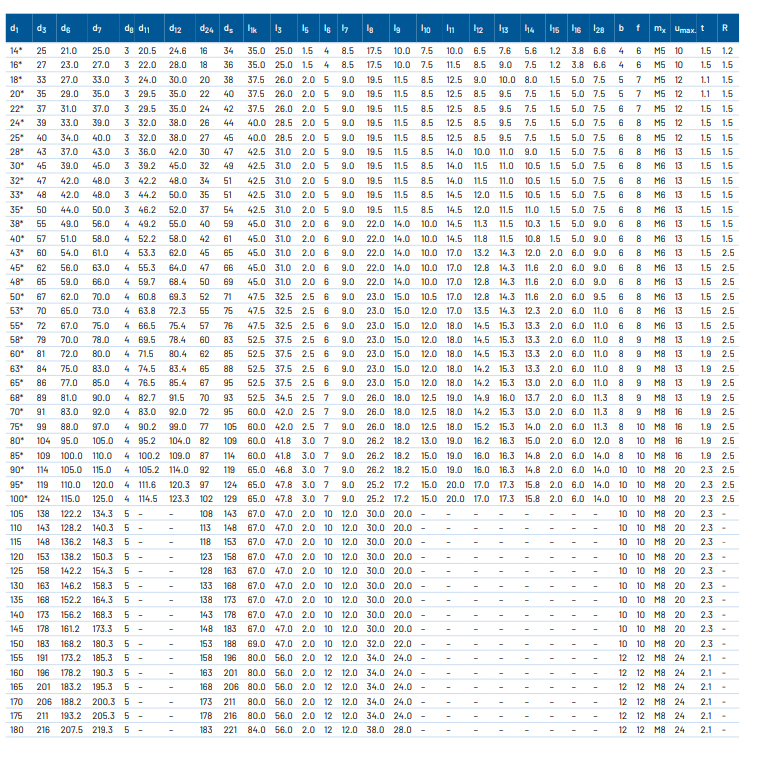

WM7N DATA SHEET OF DIMENSION (mm)

mechanical pump seal, water pump shaft seal, pump and seal

mechanical pump seal, water pump shaft seal, pump and seal