With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for M7N water pump shaft seal for marine industry eagle burgmann, We sincerely hope to determine some satisfactory relationships with you while in the near potential. We’re going to preserve you informed of our progress and anticipate building steady company relations with you.

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for m7n PUMP SEAL, Pump Shaft Seal, water pump mechanical seal, Water Pump Seal, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We’ve got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Replacement for the below mechanical seals

Burgmann M7N ,LIDERING LWS10, Latty U68, Flowserve Europac 600, Vulcan 1677, AESSEAL W07DMU, Anga V, Sterling 270, Hermetica M251.K2

Features

- For plain shafts

- Single seal

- Unbalanced

- Super-Sinus-spring or multiple springs rotating

- Independent of direction of rotation

Advantages

- Universal application opportunities

- Efficient stock keeping due to easily interchangeable faces

- Extended selection of materials

- Insensitive to low solids contents

- Flexibility in torque transmissions

- Self-cleaning effect

- Short installation length possible (G16)

- Pumping screw for media with higher viscosity

Operating Range

Shaft diameter:

d1 = 14 … 100 mm (0.55 ” … 3.94 “)

Pressure:

p1 = 25 bar (363 PSI)

Temperature:

t = -50 °C … +220 °C

(-58 °F … +428 °F)

Sliding velocity:

vg = 20 m/s (66 ft/s)

Axial movement:

d1 = up to 25 mm: ±1.0 mm

d1 = 28 up to 63 mm: ±1.5 mm

d1 = from 65 mm: ±2.0 mm

Combination Material

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Cr-Ni-Mo Steel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Rubber(MVQ)

PTFE Coated VITON

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Recommended Applications

- Process industry

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Shipbuilding

- Lube oils

- Low solids content media

- Water / sewage water pumps

- Chemical standard pumps

- Vertical screw pumps

- Gear wheel feed pumps

- Multistage pumps (drive side)

- Circulation of printing colors with viscosity 500 … 15,000 mm2/s.

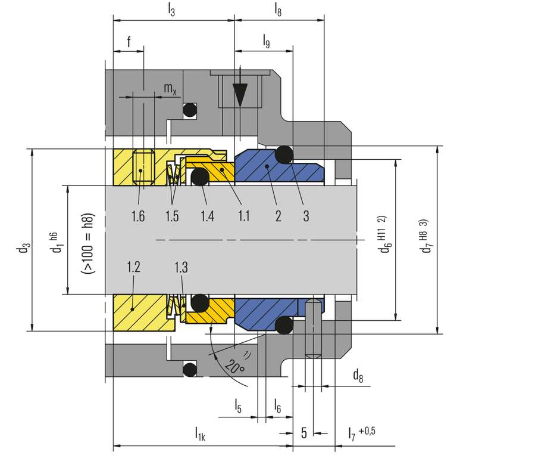

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 412.1 O-Ring

1.3 474 Thrust ring

1.4 478 Righthand spring

1.4 479 Lefthand spring

2 475 Seat (G9)

3 412.2 O-Ring

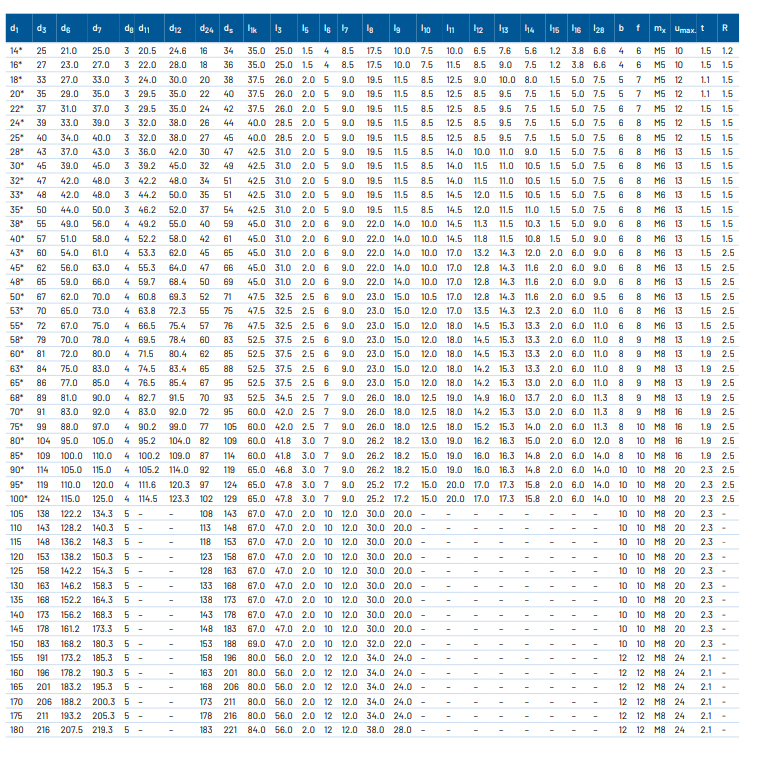

WM7N DATA SHEET OF DIMENSION (mm)

mechanical pump seal and water pump

mechanical pump seal and water pump