Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for mechanical pump seal for marine industry MG912, We, with fantastic passion and faithfulness, are willing to offer you with best services and striding forward with you to make a bright foreseeable future.

Along with the “Client-Oriented” business philosophy, a rigorous good quality management method, state-of-the-art producing devices as well as a potent R&D workforce, we always supply high quality products and solutions, outstanding products and services and aggressive costs for Mechanical Pump Seal, Pump And Seal, Water Pump Shaft Seal, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to to suit your needs of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’re confident that we’re going to have a bright prospect and to be distributed all over the world in the years to come.

Features

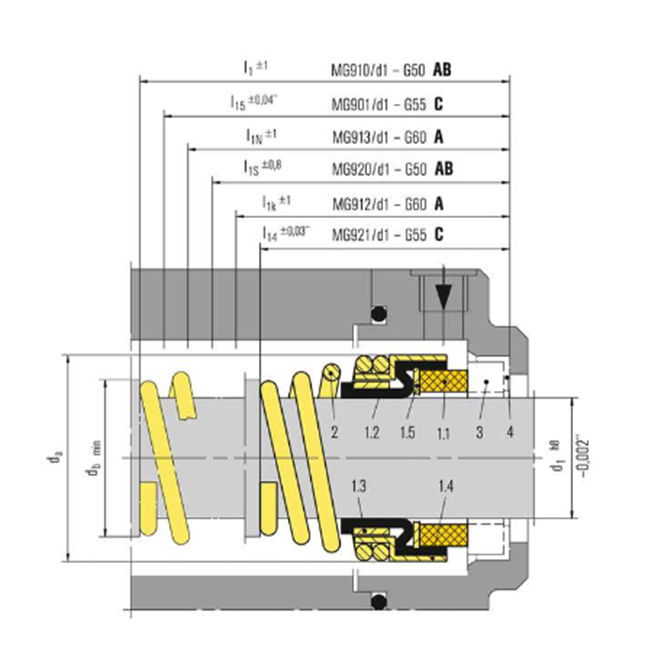

•For plain shafts

•Single spring

•Elastomer bellows rotating

•Balanced

•Independent of direction of rotation

•No torsion on bellows and spring

•Conical or cylindrical spring

•Metric and inch sizes available

•Special seat dimensions available

Advantages

•Fits into any installation space due to smallest outer seal diameter

•Important material approvals available

•Individual installation length can be achieved

•High flexibility due to extended selection of materials

Recommended applications

•Water and waste water technology

•Pulp and paper industry

•Chemical industry

•Cooling fluids

•Media with low solids content

Pressure oils for bio diesel fuels

•Circulating pumps

•Submersible pumps

•Multi-stage pumps (non-drive side)

•Water and waste water pumps

•Oil applications

Operating range

Shaft diameter:

d1 = 10 … 100 mm (0.375″ … 4″)

Pressure: p1 = 12 bar (174 PSI),

vacuum up to 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature:

t = -20 °C … +140 °C (-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ±0.5 mm

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

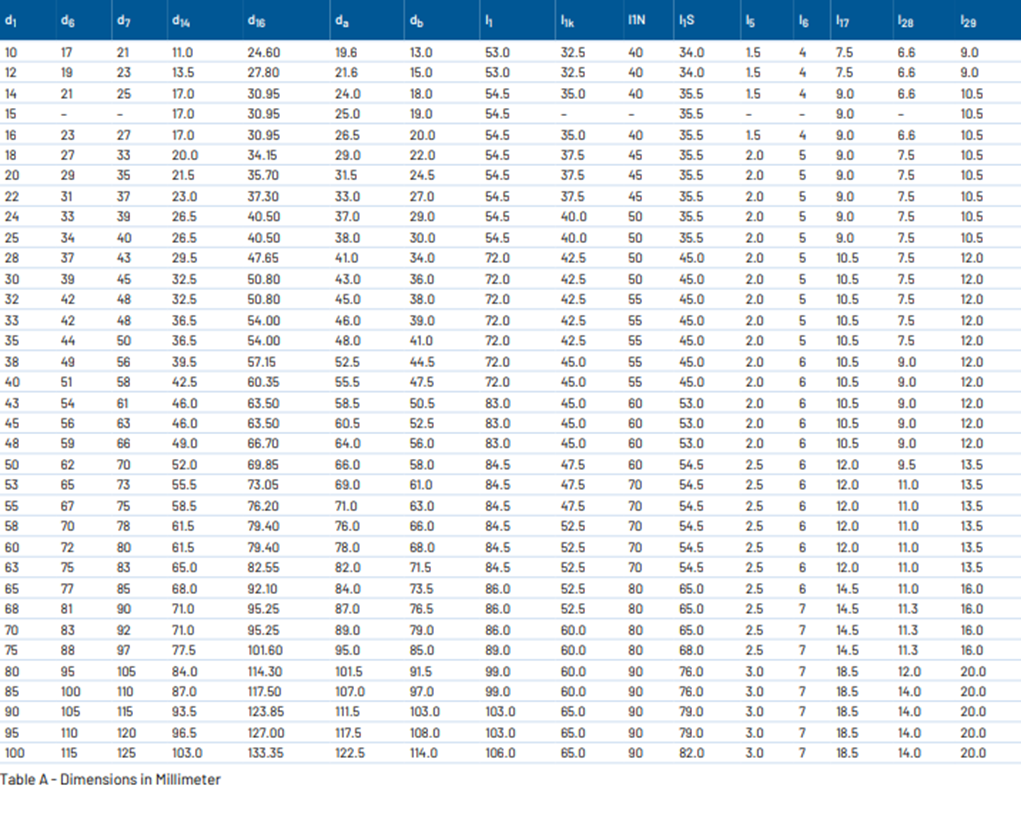

WMG912 data sheet of dimension(mm)

pump mechanical seal

pump mechanical seal