We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for mechanical pump seal type 502 for wter pump seal, Should even more info be required, remember to make contact with us at any time!

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for haft seal, seal rl=, type 502 mechani, type 502 pump seal, Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

Product Features

- With full enclosed elastomer bellows design

- Insensitive to shaft play and run out

- Bellows should not twist due to bi-directional and robust drive

- Single seal and single spring

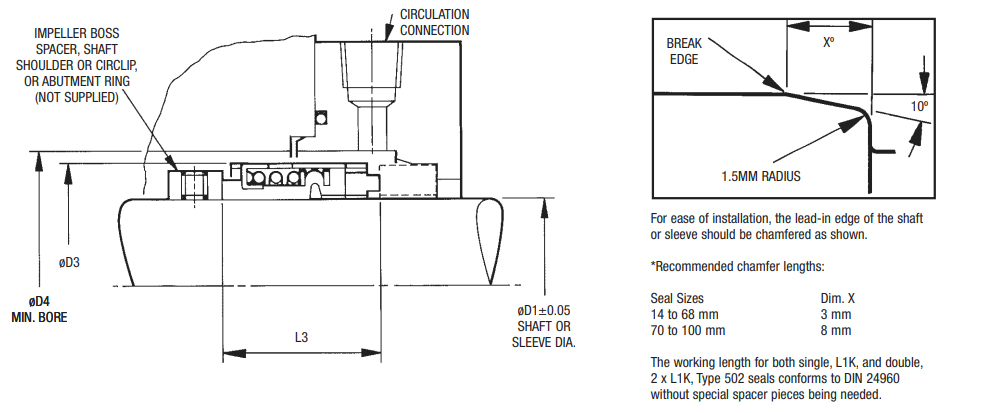

- Conform with DIN24960 standard

Design Features

• Completely assembled one-piece design for fast installation

• Unitized design incorporates positive retainer/key drive from bellows

• Non-clogging, single coil spring provides greater dependability than multiple spring designs. Will not be affected by build-up of solids

• Full convolution elastomeric bellows seal designed for confined spaces and limited gland depths. Self-aligning feature compensates for excessive shaft end play and run-out

Operation Range

Shaft diameter: d1=14…100 mm

• Temperature: -40°C to +205°C (depending on materials used)

• Pressure: up to 40 bar g

• Speed: up to 13 m/s

Notes: The range of preesure,temperature and speed is depend on seals combination materials

Recommended Application

• Paints and inks

• Water

• Weak acids

• Chemical processing

• Conveyor and industrial equipment

• Cryogenics

• Food processing

• Gas compression

• Industrial blowers and fans

• Marine

• Mixers and agitators

• Nuclear service

• Offshore

• Oil and refinery

• Paint and ink

• Petrochemical processing

• Pharmaceutical

• Pipeline

• Power generation

• Pulp and paper

• Water systems

• Wastewater

• Treatment

• Water desalination

Combination Materials

Rotary Face

Carbon graphite resin impregnated

Silicon carbide (RBSIC)

Hot-Pressing Carbon

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Metal Parts

Stainless Steel (SUS304)

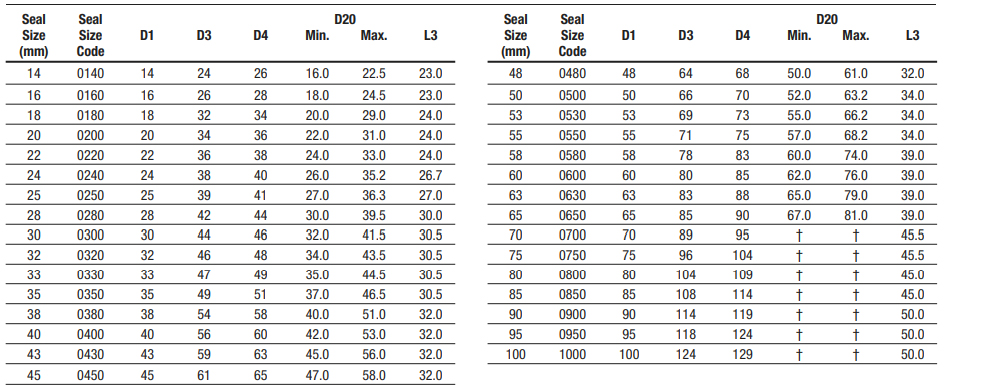

W502 dimension data sheet (mm)