We pursue the administration tenet of “Quality is top-quality, Company is supreme, Track record is first”, and will sincerely create and share success with all purchasers for MG1 rubber bellow mechanical seal for marine industry, And we are able to enable on the lookout for any products with the customers’ needs. Make sure deliver the best Assistance, the most beneficial High-quality, The quickly Delivery.

We pursue the administration tenet of “Quality is top-quality, Company is supreme, Track record is first”, and will sincerely create and share success with all purchasers for burgmann pump seal, Mechanical Pump Seal, Pump Shaft Seal, Water Pump Shaft Seal, Our faith is to be honest first, so we just supply high quality goods to our customers. Genuinely hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products and solutions !

Replacement for below mechanical seals

AESSEAL B02, BURGMANN MG1, FLOWSERVE 190

Features

- For plain shafts

- Single and dual seal

- Elastomer bellows rotating

- Balanced

- Independent of direction of rotation

- No torsion on bellows

Advantages

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Universal application opportunities

- Important material certifications available

- High flexibility due to wide offer on materials

- Suitable for low-end sterile applications

- Special design for hot water pumps (RMG12) available

- Dimension adaptions and additional seats available

Operating Range

Shaft diameter:

d1 = 10 … 100 mm (0.39″ … 3.94″)

Pressure: p1 = 16 bar (230 PSI),

vacuum … 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C

(-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0,08″)

Combination Material

Rotary Face

Carbon graphite resin impregnated

Hot-Pressing carbon

Silicon carbide (RBSIC)

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Metal Parts

Stainless Steel (SUS304)

Recommended Applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries (solids up to 5 % by weight)

- Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

- Oil applications

Notes

The WMG1 can also be used as a multiple seal in tandem or in a back-to-back arrangement. Installation proposals available upon request.

Dimension adaptations for specific conditions, e. g. shaft in inches or special seat dimensions are available upon request.

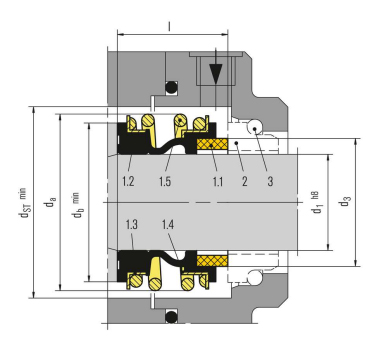

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 481 Bellows

1.3 484.2 L-ring (spring collar)

1.4 484.1 L-ring (spring collar)

1.5 477 Spring

2 475 Seat

3 412 O-Ring or cup rubber

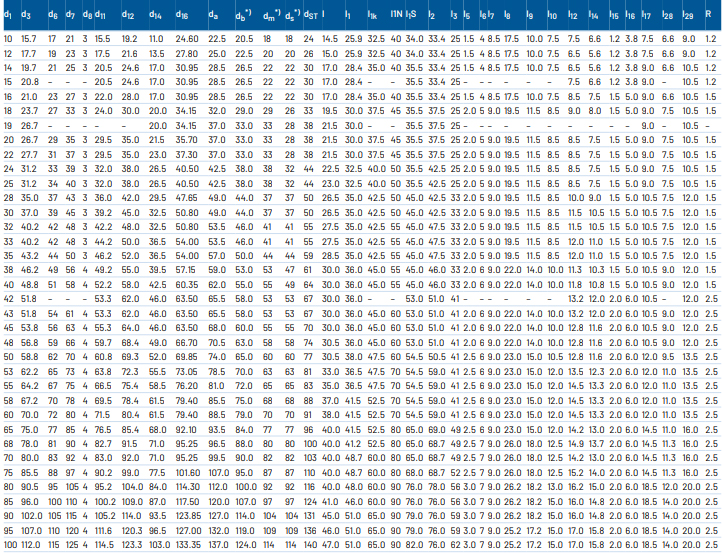

WMG1 dimension date sheet(mm)

pump and seal, mechanical pump seal, water pump seal