We usually think and practice corresponding to your change of circumstance, and grow up. We goal at the achievement of a richer mind and body plus the living for MG912 mechanical pump seal for marine industry for marine industry, We fully welcome clients from all around the planet to determine stable and mutually beneficial small business interactions, to have a vivid long term together.

We usually think and practice corresponding to your change of circumstance, and grow up. We goal at the achievement of a richer mind and body plus the living for Mechanical Pump Seal, mechanical seal for marine industry, Single Spring Mechanical Seal, Item have passed by means of the national qualified certification and been well received in our main industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to offer you the most beneficial service and solutions. Need to you be interested in our company and solutions, you should make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you’ll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Remember to feel absolutely free to speak to us for organization. nd we believe we’ll share the best trading practical experience with all our merchants.

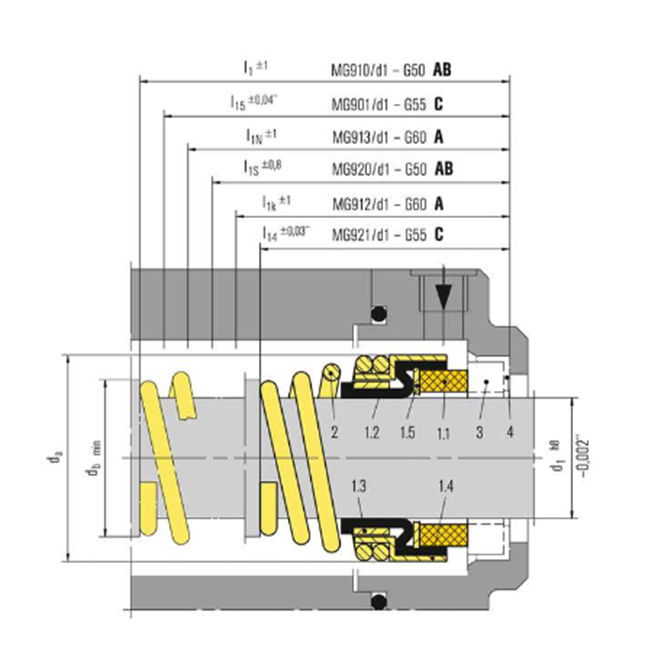

Features

•For plain shafts

•Single spring

•Elastomer bellows rotating

•Balanced

•Independent of direction of rotation

•No torsion on bellows and spring

•Conical or cylindrical spring

•Metric and inch sizes available

•Special seat dimensions available

Advantages

•Fits into any installation space due to smallest outer seal diameter

•Important material approvals available

•Individual installation length can be achieved

•High flexibility due to extended selection of materials

Recommended applications

•Water and waste water technology

•Pulp and paper industry

•Chemical industry

•Cooling fluids

•Media with low solids content

Pressure oils for bio diesel fuels

•Circulating pumps

•Submersible pumps

•Multi-stage pumps (non-drive side)

•Water and waste water pumps

•Oil applications

Operating range

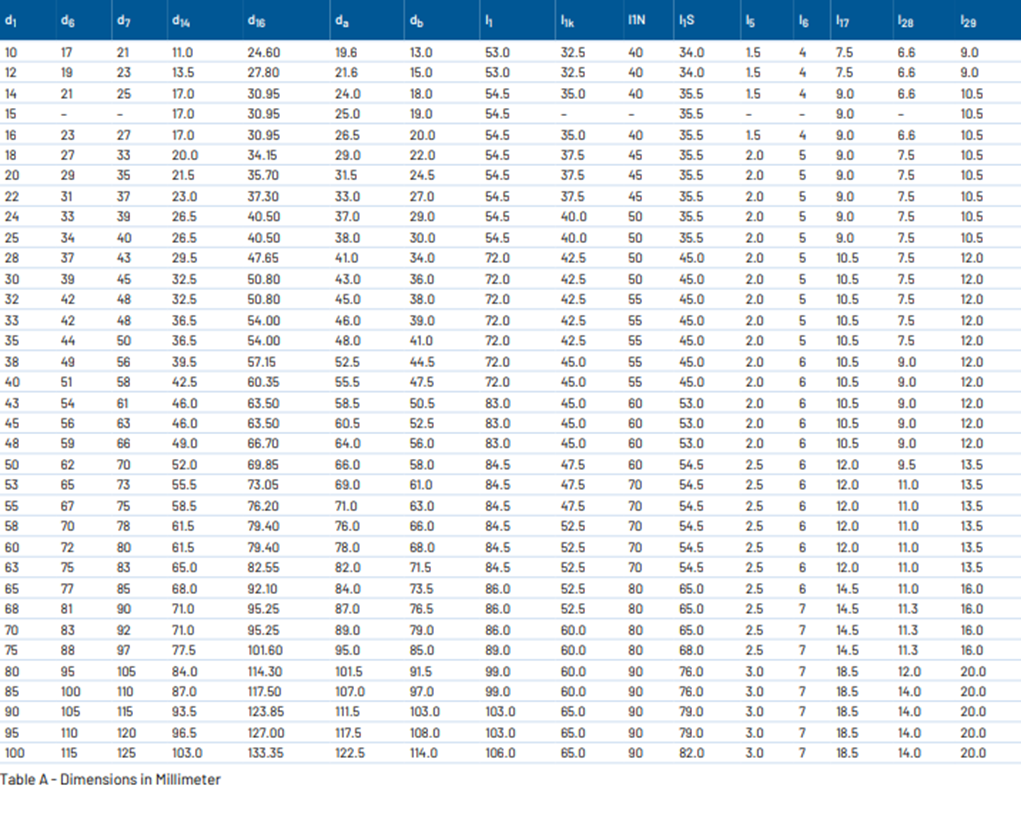

Shaft diameter:

d1 = 10 … 100 mm (0.375″ … 4″)

Pressure: p1 = 12 bar (174 PSI),

vacuum up to 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature:

t = -20 °C … +140 °C (-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ±0.5 mm

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

WMG912 data sheet of dimension(mm)

water pump shaft seal, mechanical pump seal

water pump shaft seal, mechanical pump seal