“Quality initially, Honesty as base, Sincere company and mutual profit” is our idea, in order to create repeatedly and pursue the excellence for O ring H7N water pump mechanical seal for marine industry, In case you pursuit the Hi-quality, Hi-stable, Aggressive price elements, corporation name is your greatest choice!

“Quality initially, Honesty as base, Sincere company and mutual profit” is our idea, in order to create repeatedly and pursue the excellence for Mechanical Pump Seal, O Ring Mechanical Seal, Pump And Seal, Water Pump Shaft Seal, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

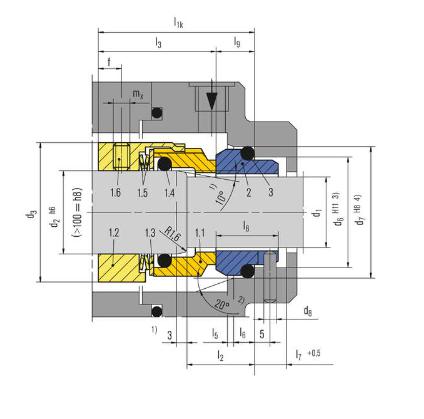

Features

•For stepped shafts

•Single seal

•Balanced

•Super-Sinus-spring or multiple springs rotating

•Independent of direction of rotation

•Integrated pumping device available

•Variant with seat cooling available

Advantages

•Universal application opportunities (standardization)

•Efficient stock keeping due to easily interchangeable faces

•Extended selection of materials

•Flexibility in torque transmissions

•Self-cleaning effect

•Short Installation length possible (G16)

Recommended applications

•Process industry

•Oil and gas industry

•Refining technology

•Petrochemical industry

•Chemical industry

•Power plant technology

•Pulp and paper industry

•Food and beverage industry

•Hot water applications

•Light hydrocarbons

•Boiler feed pumps

•Process pumps

Operating range

Shaft diameter:

d1 = 14 … 100 mm (0.55″ … 3.94″)

(Single spring: d1 = max. 100 mm (3.94″))

Pressure:

p1 = 80 bar (1,160 PSI) for d1 = 14 … 100 mm,

p1 = 25 bar (363 PSI) for d1 = 100 … 200 mm,

p1 = 16 bar (232 PSI) for d1 > 200 mm

Temperature:

t = -50 °C … 220 °C (-58 °F … 428 °F)

Sliding velocity: vg = 20 m/s (66 ft/s)

Axial movement:

d1 up to 22 mm: ± 1.0 mm

d1 24 up to 58 mm: ± 1.5 mm

d1 from 60 mm: ± 2.0 mm

Combination Materials

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Cr-Ni-Mo Steel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Rubber(MVQ)

PTFE Coated VITON

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

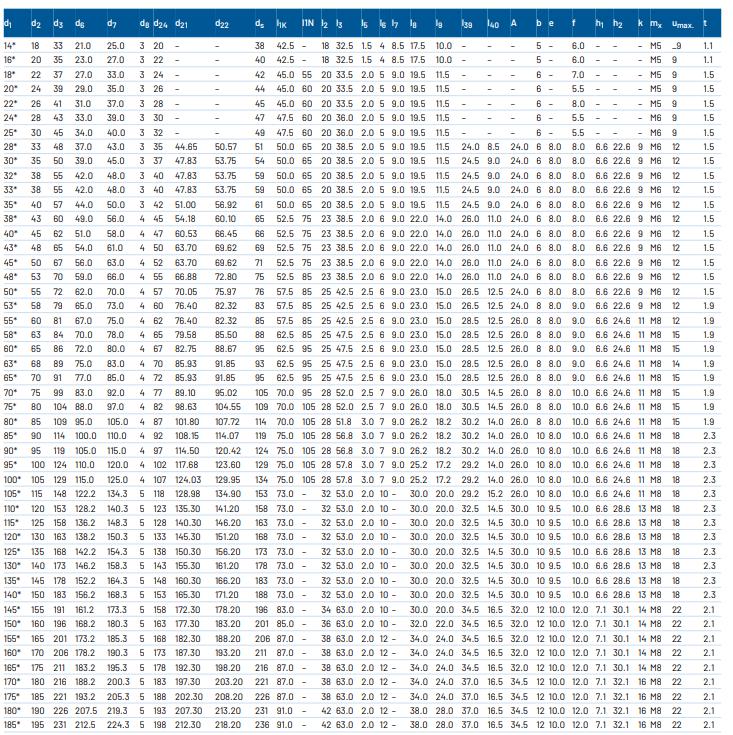

WH7N data sheet of dimension (mm)

WAVE SPRINGS ARE COMPACT BIDIRECTIONAL SEALS ORIGINALLY DESIGNED FOR SHORT WORKING LENGTH AND HYGIENIC REQUIREMENTS.

Wave springs are mechanical seals designed to replace conventional round wire compression springs in applications that require a tight load deflection specification in a space critical environment. They provide a more even face loading than a Parallel or Taper Spring, and a smaller envelope requirement to achieve a similar face loading.

Bi-directional mechanical seals offer proven seal design and wave spring technology, in a range of material combinations. This is enhanced by superior design features, all at very competitive prices.

H7N mechanical pump seal for marine industry