We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for O ring shaft seal for marine industry for OEM pump seal, Our enterprise has already build a experienced, creative and responsible group to create consumers while using the multi-win principle.

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Mechanical Pump Seal, Nippon mechanical seal, O Ring Mechanical Seal, Water Pump Shaft Seal, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a “people-oriented, meticulous manufacturing, brainstorm, construct brilliant” organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we’ve been likely to be pleased to serve you.

Features

- Robust O-Ring mounted Mechanical Seal

- Capable of many shaft-sealing duties

- Unbalanced pusher-type Mechanical Seal

Combination Material

Rotary Ring

Carbon, SIC, SSIC, TC

Stationary Ring

Carbon, Ceramic, SIC, SSIC, TC

Secondary Seal

NBR/EPDM/Viton

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Operating Ranges

- Mediums: Water, oil, acid, alkali, etc.

- Temperature: -20°C~180°C

- Pressure: ≤1.0MPa

- Speed: ≤ 10 m/Sec

Maximum Operating Pressure Limits primarily depend upon Face Materials, Shaft Size, Speed and Media.

Advantages

Pillar seal is widely used for big sea ship pump, In order to prevent corrosion by sea water, it is furnished with mating face of plasma flame fusible ceramics. so it is a marine pump seal with ceramic coated layer on the seal face, offer more resistance against sea water.

It can be used in reciprocating and rotary movement and can adapt to most fluids and chemicals. Low friction coefficient, no crawling under precise control, good anti-corrosion capability and good dimensional stability. It can withstand rapid temperature changes.

Suitable Pumps

Naniwa Pump, Shinko Pump, Teiko Kikai, Shin Shin for BLR Circ water, SW Pump and many other applications.

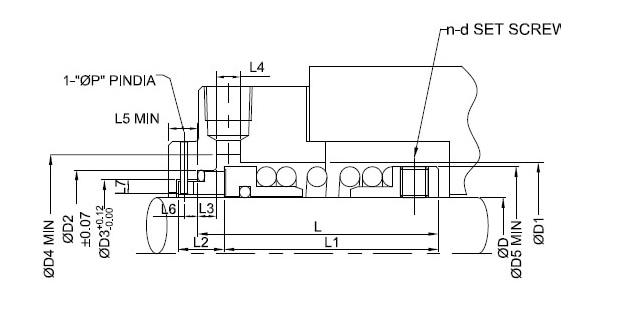

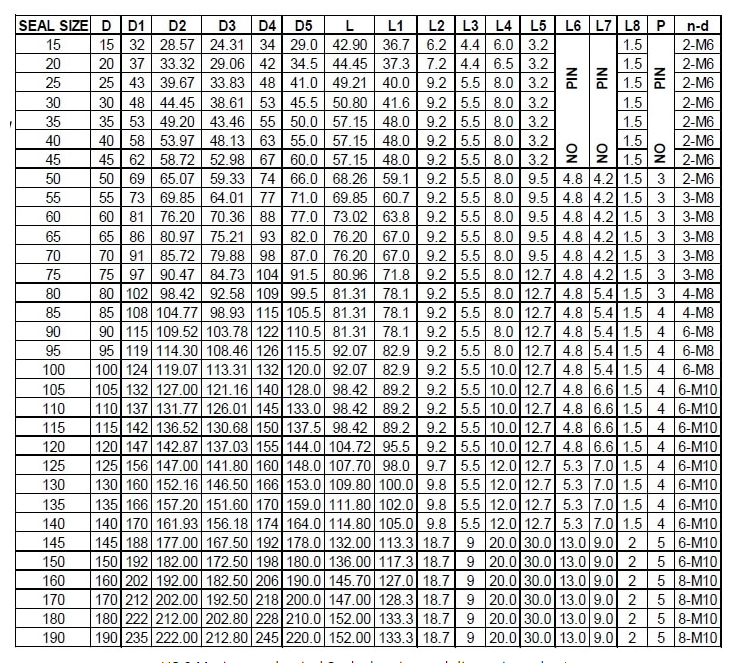

WUS-2 dimension data sheet (mm)

Nippon Pillar mechanical seal

Nippon Pillar mechanical seal