“Control the standard by the details, show the power by quality”. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for pump mechanical M3N for water pump, Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software growth are our distinguishing feature.

“Control the standard by the details, show the power by quality”. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Mechanical Seal, Mechanical Shaft Seal, water mechanical seal, Water Pump Seal, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we’ll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Analog to the following mechanical seals

- Burgmann M3N

- Flowserve Pac-Seal 38

- Vulcan Type 8

- AESSEAL T01

- ROTEN 2

- ANGA A3

- Lidering M211K

Features

- For plain shafts

- Single seal

- Unbalanced

- Rotating conical spring

- Dependent on direction of rotation

Advantages

- Universal application opportunities

- Insensitive to low solids content

- No damage of the shaft by set screws

- Large choice of materials

- Short installation lengths possible (G16)

- Variants with shrink-fitted seal face available

Recommended Applications

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Building services industry

- Food and beverage industry

- Sugar industry

- Low solids content media

- Water and sewage water pumps

- Submersible pumps

- Chemical standard pumps

- Eccentric screw pumps

- Cooling water pumps

- Basic sterile applications

Operating Range

Shaft diameter:

d1 = 6 … 80 mm (0,24″ … 3,15″)

Pressure: p1 = 10 bar (145 PSI)

Temperature:

t = -20 °C … +140 °C (-4 °F … +355 °F)

Sliding velocity: vg = 15 m/s (50 ft/s)

Axial movement: ±1.0 mm

Combination Material

Rotary Face

Silicon carbide (RBSIC)

Tungsten carbide

Cr-Ni-Mo Steel (SUS316)

Surface hard facing tungsten carbide

Stationary Seat

Carbon graphite resin impregnated

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Left rotation: L Right rotation:

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

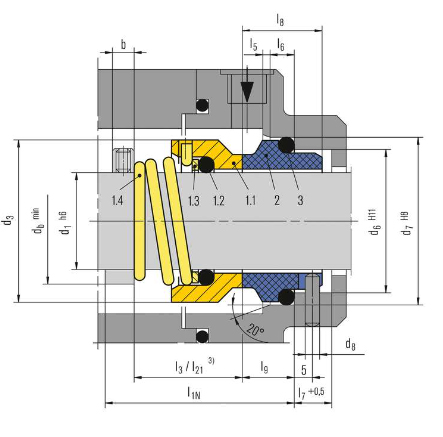

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 412.1 O-Ring

1.3 474 Thrust ring

1.4 478 Righthand spring

1.4 479 Lefthand spring

2 475 Seat (G9)

3 412.2 O-Ring

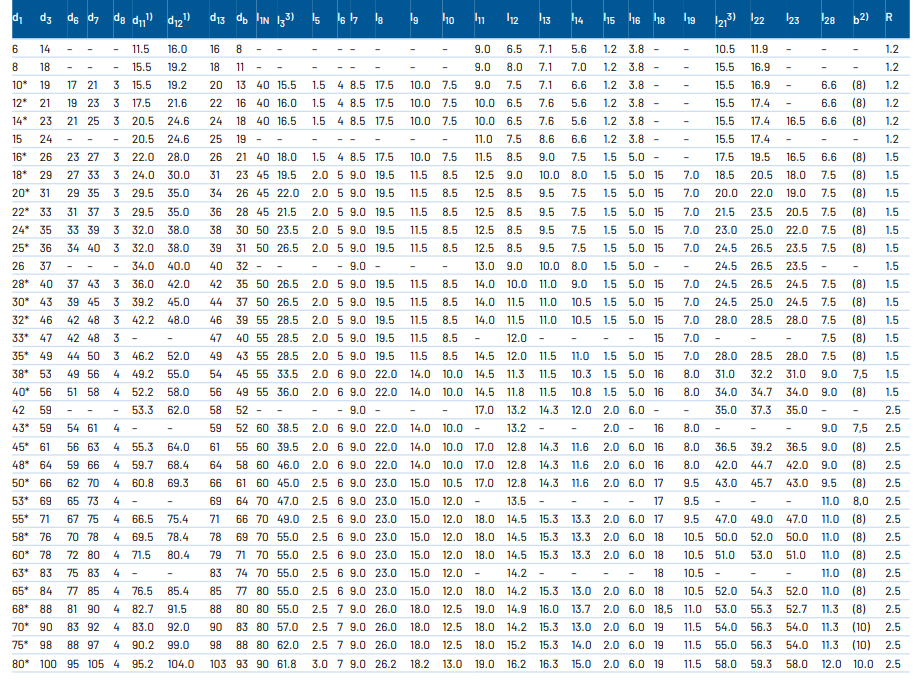

WM3N dimension data sheet(mm)

We can produce mechanical seal for mechanical seal

We can produce mechanical seal for mechanical seal