We try for excellence, service the customers”, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for silicone carbide type 2100 mechanical seal for water pump, We’ve been trying to get for intensive cooperation with truthful customers, accomplishing a new induce of glory with customers and strategic partners.

We try for excellence, service the customers”, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Pump And Seal, Pump Mechanical Seal, silicone carbide seal, Water Pump Shaft Seal, Company name, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Features

Unitized construction allows for fast and easy installation and replacement. Design fits DIN24960, ISO 3069 and ANSI B73.1 M-1991 standards.

Innovative bellows design is pressure-supported and will not crease or fold under high pressure.

Non-clogging, single-coil spring keeps seal faces closed and properly tracking during all phases of operation.

Positive drive through interlocking tangs will not slip or break free during upset conditions.

Available in the widest array of material options, including high performance silicon carbides.

Operation Range

Shaft diameter: d1=10…100mm(0.375” …3.000”)

Pressure: p=0…1.2Mpa(174psi)

Temperature: t = -20 °C …150 °C(-4°F to 302°F)

Sliding velocity: Vg≤13m/s(42.6ft/m)

Notes: The range of pressure, temperature and sliding velocity is depend on seals combination materials

Combination Materials

Rotary Face

Carbon graphite resin impregnated

Hot-Pressing carbon

Silicon carbide (RBSIC)

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Elastomer

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless steel (SUS304, SUS316)

Metal Parts

Stainless steel (SUS304, SUS316)

Applications

Centrifugal pumps

Vacuum pumps

Submerged motors

Compressor

Agitation equipment

Decelerators for sewage treatment

Chemical engineering

Pharmacy

Paper making

Food processing

Mediums: clean water and sewage, mostly used in industries such as sewage treatment and papermaking.

Customization: Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

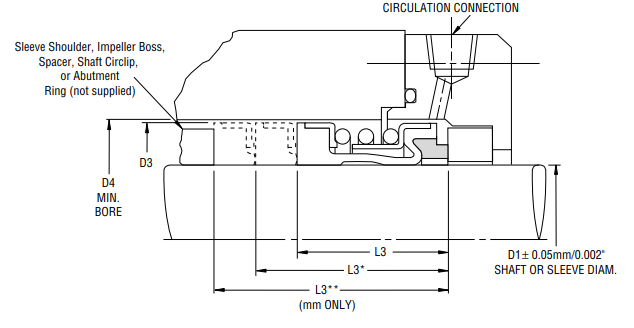

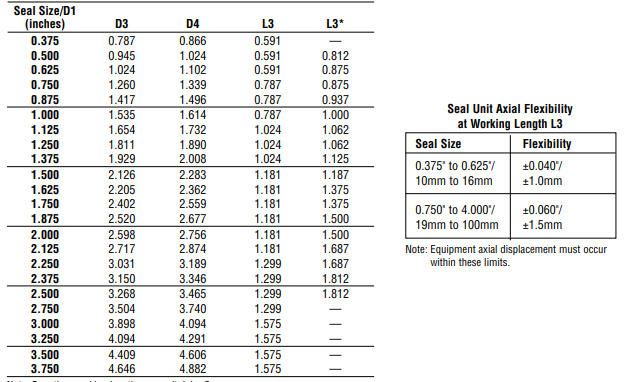

W2100 DIMENSION DATA SHEET (INCHES)

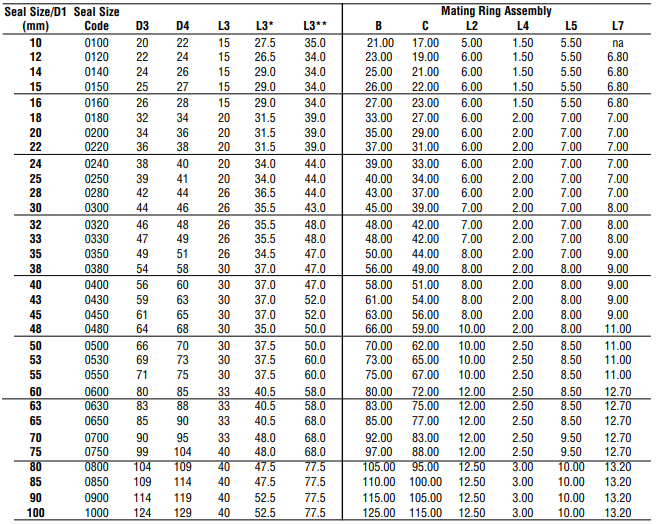

DIMENSION DATA SHEET (MM)

L3= Standard seal working length.

L3*= Working length for seals to DIN L1K (seat not included).

L3**= Working length for seals to DIN L1N (seat not included).We can produce mechanical seals for 2100 with a very competitive price