“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for single spring mechanical seal MG912 for marine industry, Through additional than 8 years of small business, we have now accumulated rich experience and advanced technologies during the manufacturing of our products.

“Sincerity, Innovation, Rigorousness, and Efficiency” may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Mechanical Pump Seal, mechanical seal MG912, Single Spring Mechanical Seal, Water Pump Shaft Seal, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we present, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and comprehensive parameters and any other info weil be sent for you timely for your inquiries. So please make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We have been confident that we’re likely to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We’re searching forward for your inquiries.

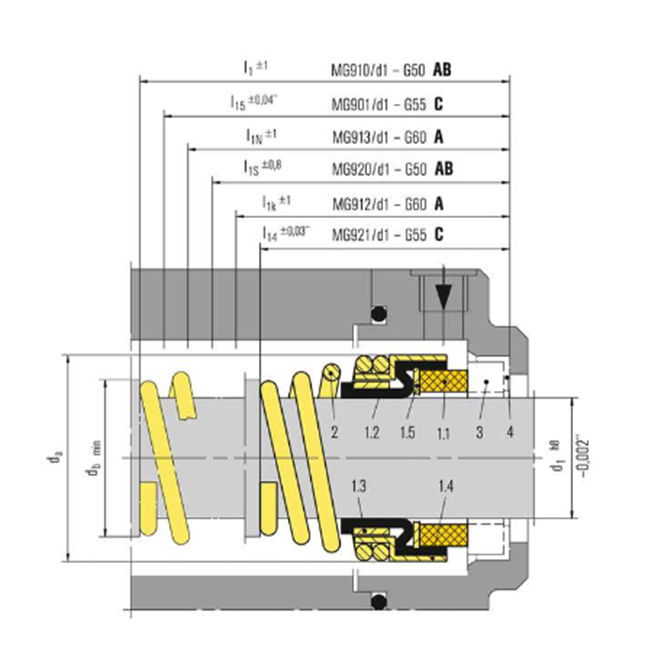

Features

•For plain shafts

•Single spring

•Elastomer bellows rotating

•Balanced

•Independent of direction of rotation

•No torsion on bellows and spring

•Conical or cylindrical spring

•Metric and inch sizes available

•Special seat dimensions available

Advantages

•Fits into any installation space due to smallest outer seal diameter

•Important material approvals available

•Individual installation length can be achieved

•High flexibility due to extended selection of materials

Recommended applications

•Water and waste water technology

•Pulp and paper industry

•Chemical industry

•Cooling fluids

•Media with low solids content

Pressure oils for bio diesel fuels

•Circulating pumps

•Submersible pumps

•Multi-stage pumps (non-drive side)

•Water and waste water pumps

•Oil applications

Operating range

Shaft diameter:

d1 = 10 … 100 mm (0.375″ … 4″)

Pressure: p1 = 12 bar (174 PSI),

vacuum up to 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking

Temperature:

t = -20 °C … +140 °C (-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ±0.5 mm

Combination material

Stationary Ring: Ceramic, Carbon, SIC, SSIC, TC

Rotary Ring: Ceramic, Carbon, SIC, SSIC, TC

Secondary Seal: NBR/EPDM/Viton

Spring and Metal Parts: SS304/SS316

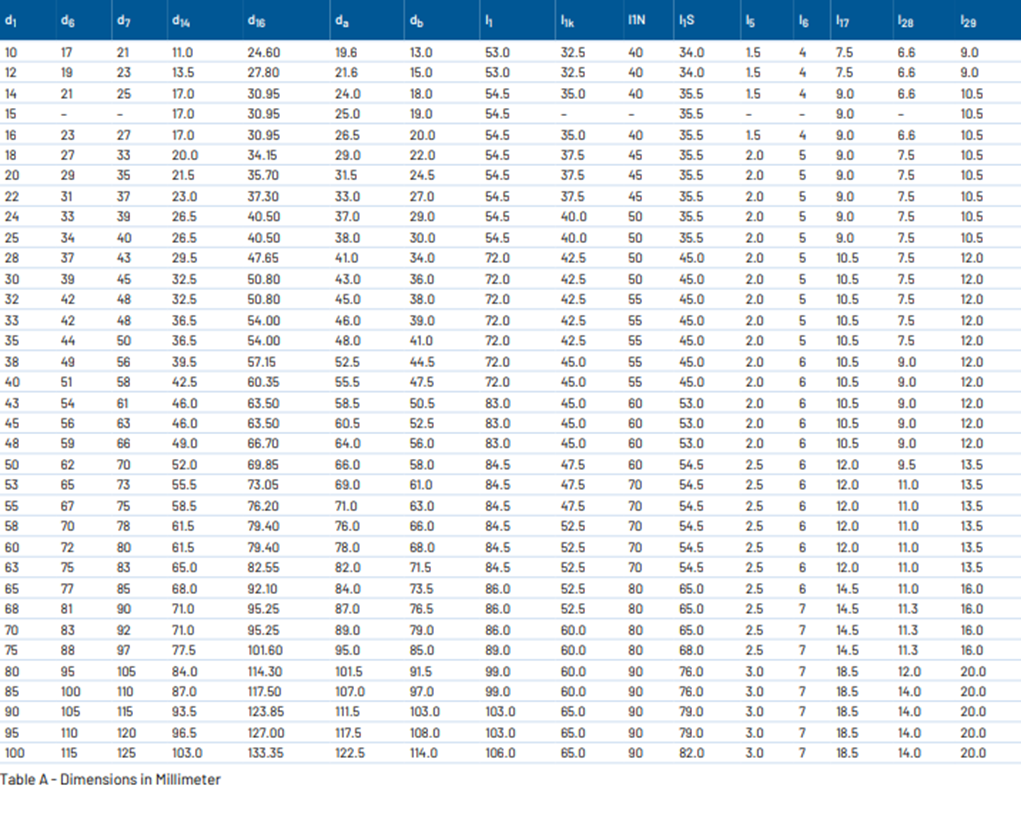

WMG912 data sheet of dimension(mm)

water pump mechanical seal, pump shaft seal, mechanical pump seal

water pump mechanical seal, pump shaft seal, mechanical pump seal