“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for standard mechanical seal type 502, Please ship us your specifications and demands, or truly feel totally free to get hold of us with any questions or inquiries that you may have.

“Quality to start with, Honesty as base, Sincere company and mutual profit” is our idea, as a way to build constantly and pursue the excellence for Fluid Sealing, Fluid Sealing Solution, Mechanical Water Seal, pump seal 502, Pump Shaft Seal, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Product Features

- With full enclosed elastomer bellows design

- Insensitive to shaft play and run out

- Bellows should not twist due to bi-directional and robust drive

- Single seal and single spring

- Conform with DIN24960 standard

Design Features

• Completely assembled one-piece design for fast installation

• Unitized design incorporates positive retainer/key drive from bellows

• Non-clogging, single coil spring provides greater dependability than multiple spring designs. Will not be affected by build-up of solids

• Full convolution elastomeric bellows seal designed for confined spaces and limited gland depths. Self-aligning feature compensates for excessive shaft end play and run-out

Operation Range

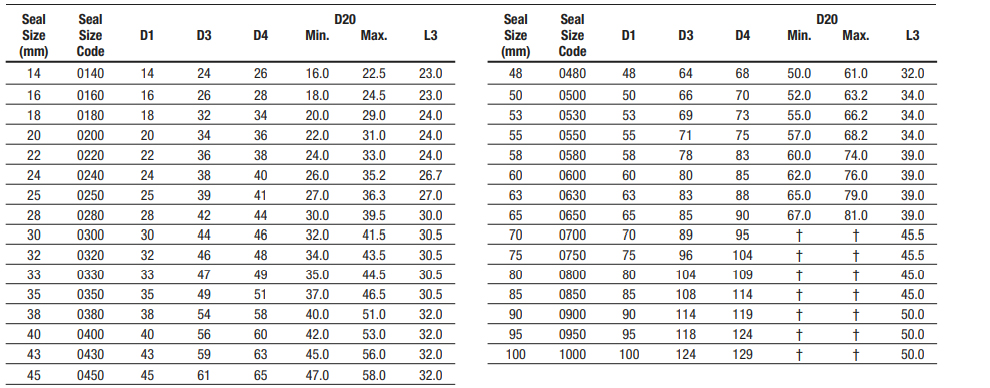

Shaft diameter: d1=14…100 mm

• Temperature: -40°C to +205°C (depending on materials used)

• Pressure: up to 40 bar g

• Speed: up to 13 m/s

Notes: The range of preesure,temperature and speed is depend on seals combination materials

Recommended Application

• Paints and inks

• Water

• Weak acids

• Chemical processing

• Conveyor and industrial equipment

• Cryogenics

• Food processing

• Gas compression

• Industrial blowers and fans

• Marine

• Mixers and agitators

• Nuclear service

• Offshore

• Oil and refinery

• Paint and ink

• Petrochemical processing

• Pharmaceutical

• Pipeline

• Power generation

• Pulp and paper

• Water systems

• Wastewater

• Treatment

• Water desalination

Combination Materials

Rotary Face

Carbon graphite resin impregnated

Silicon carbide (RBSIC)

Hot-Pressing Carbon

Stationary Seat

Aluminium oxide (Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Metal Parts

Stainless Steel (SUS304)

W502 dimension data sheet (mm)