Replacement of Below Mechanical Seals

Burgmann MG901, John crane Type 1, AES P05U, Flowserve 51, Vulcan A5

Technical Features

- Unbalanced

- Single Spring

- Bi-directional

- Elastomer Bellows

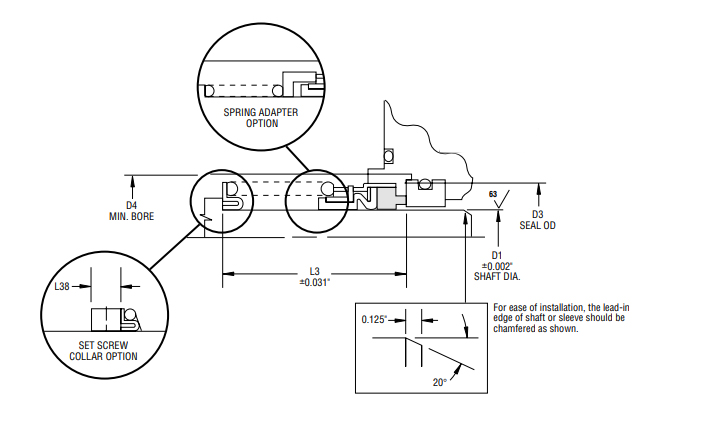

- Set screw lock collars available

Designed Features

- To absorb both breakout and running torque, the seal is designed with a drive band and drive notches that eliminate overstressing of bellows. Slippage is eliminated, protecting the shaft and sleeve from wear and scoring.

- Automatic adjustment compensates for abnormal shaft-end play, run-out, primary ring wear and equipment tolerances. Uniform spring pressure compensates for axial and radial shaft movement.

- Special balancing accommodates higher-pressure applications, greater operating speeds and lower wear.

- Non-clogging, single-coil spring allows for greater dependability than multiple spring designs. Will not run foul due to fluid contact.

- Low drive torque improves performance and reliability.

Operating Range

Temperature: -40°C to 205°C/-40°F to 400°F (depending on materials used)

Pressure: 1: up to 29 bar g/425 psig 1B: up to 82 bar g/1200 psig

Speed: 20 M/S 4000 FPM

Standard size:12-100mm or 0.5-4.0 inch

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination materials

Combination Material

Rotary Face

Carbon graphite resin impregnated

Tungsten carbide

Silicon carbide (RBSIC)

Stationary Seat

Aluminium oxide(Ceramic)

Silicon carbide (RBSIC)

Tungsten carbide 1

Auxiliary Seal

Nitrile-Butadiene-Rubber (NBR)

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304, SUS316)

Metal Parts

Stainless Steel (SUS304, SUS316)

Recommended Applications

- Water and waste water technology

- Petroleum chemical industry

- Industrial pumps

- Process pumps

- Other Rotating Equipment

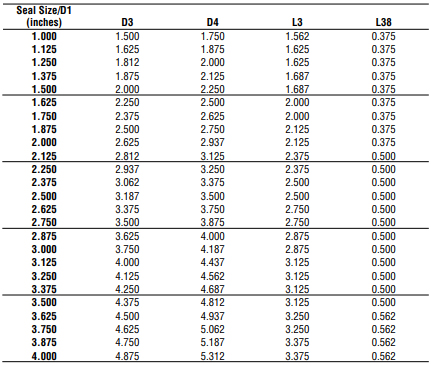

TYPE W1 dimension data sheet (inches)