Features

•Double wave spring for strength and reliability

•Compact design for confined spaces

•Minimal shaft wear

•Suitable to DIN24960 (EN12756) dimensions

Recommended applications

•Process industry

•Chemical industry

•Pulp and paper industry

•Water and waste water technology

•Shipbuilding

•Lube oils

•Low solids content media

•Water / sewage water pumps

•Chemical standard pumps

•Vertical screw pumps

•Gear wheel feed pumps

•Multistage pumps (drive side)

•Circulation of printing colors with viscosity 500 ... 15,000 mm2/s.

Operating range

•Temperature: -30°C to +140°C

•Pressure: Up to 22 bar (320 psi)

•For full Performance Capabilities please download data sheet

•Limits are for guidance only. Product performance is dependent on materials and other operating conditions.

Combination Materials

Stationary Ring: Carbon/SIC/TC

Rotary face: Carbon/Sic/TC

Metal part: SS304, SS316

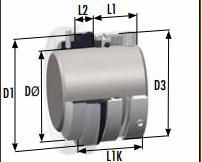

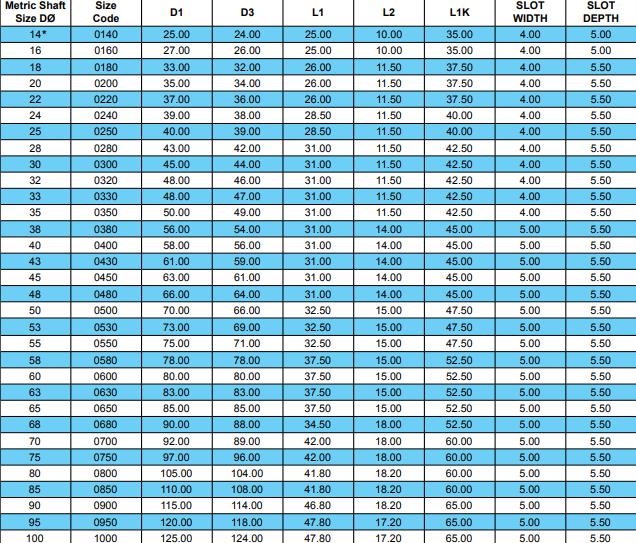

W1677 data sheet of dimension (mm)

Specifications of Wave Spring Mechanical Seals

- Seal Characteristics : Single acting, Unbalanced, Inside mounted, Independent of direction of rotation

- Application : Ligh abrasive slurry, Light sewage water, High viscosity fluid, General & light chemicals

- Seal Face Materials : Carbon, Tungsten carbide, Ceramic

- Metal Parts : SS316, SS304 Secondary Seal: Elastomers, PTFE

Application of wave spring mechanical seals

Wave Spring seals are internally mounted which are non-clogging.This type of mechanical seals are widely used in centrifugal pumps and high viscosity handling pumps in purification plants, pulp & paper, chemical, petrochemical and sugar industries, brewery and pharmaceutical applications. Single Wave spring seals are designed for bi-directional and work with high viscous, abrasive media ,water, oils, fuels, low aggressive chemical substances and liquids containing solid particles. The spare parts are interchangeable without modification. seal faces are easily inserted. Wave Springs Improve Mechanical Seal Design. Mechanical seals are used for the sealing of rotating shafts against a stationary housing, such as pumps.

How to order

In ordering mechanical seal, you are requested to give us

complete information as specified below:

1. Purpose: For which equipments or what factory use.

2. Size: Diameter of the seal in millimeter or inches

3. Material: what kind of material, strength requirement.

4. Coating: stainless steel, ceramic, hard alloy or silicon carbide

5. Remarks: Shipping marks and any other special requirement.