We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for water pump mechanical seal replace burgmann HJ92N, Our firm warmly welcome friends from everywhere in the globe to visit, examine and negotiate business enterprise.

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Pump And Seal, Pump Shaft Seal, TC mechanical seal, water pump mechanical seal, After 13 years of researching and developing goods, our brand can represent wide range of products and solutions with outstanding quality in world market. We have now completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

Features

- For unstepped shafts

- Single seal

- Balanced

- Independent of direction of rotation

- Encapsulated rotating spring

Advantages

- Especially designed for solids containing and highly viscous media

- Springs are protected from the product

- Rugged and reliable design

- No damage of the shaft by dynamically loaded O-Ring

- Universal application

- Variant for operation under vacuum available

- Variants for sterile operation available

Operating Range

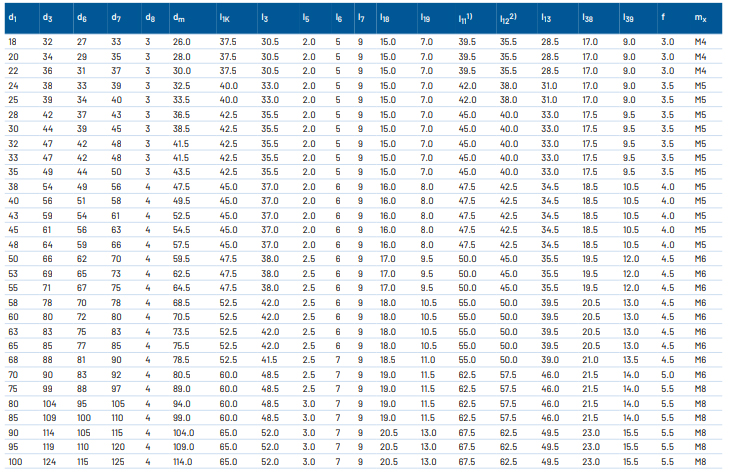

Shaft diameter:

d1 = 18 … 100 mm (0.625″ … 4″)

Pressure:

p1*) = 0.8 abs…. 25 bar (12 abs. … 363 PSI)

Temperature:

t = -50 °C … +220 °C (-58 °F … +430 °F)

Sliding velocity: vg = 20 m/s (66 ft/s)

Axial movement: ±0.5 mm

* An integral stationary seat lock is not needed within the permissible low pressure range. For prolonged operation under vacuum it is necessary to arrange for quenching on the atmospheric side.

Combination Materials

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Antimony Impregnated Carbon

Stationary Seat

Silicon carbide (RBSIC)

Tungsten carbide

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Recommended Applications

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Food and beverage industry

- Sugar industry

- Dirty, abrasive and solids containing media

- Thick juice (70 … 75 % sugar content)

- Raw sludge, sewage slurries

- Raw sludge pumps

- Thick juice pumps

- Conveying and bottling of dairy products

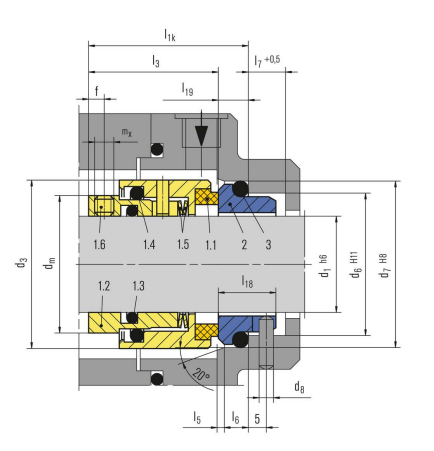

Item Part no. to DIN 24250

Description

1.1 472/473 Seal face

1.2 485 Drive collar

1.3 412.2 O-Ring

1.4 412.1 O-Ring

1.5 477 Spring

1.6 904 Set screw

2 475 Seat (G16)

3 412.3 O-Ring

WHJ92N data sheet of dimension(mm)

We can produce wave spring mechanical seals for water pump

We can produce wave spring mechanical seals for water pump