We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for water pump mechanical seal replacement John crane type 1A, Our firm is dedicated to offering customers with substantial and secure top quality items at competitive cost, earning every customer contented with our services.

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for John Crane type 1A, mechanical seal type 1A, water pump seal 1A, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of “Quality First, Customer Paramount, Sincerity and Innovation” in our mind, We’ve achieved great progress in the past years. Clients are welcomed to buy our standard solutions, or send us requests. You are going to be impressed by our quality and price. Please contact us now!

Features

To absorb both breakout and running torque, the seal is designed with a drive band and drive notches that eliminate overstressing of bellows. Slippage is eliminated, protecting the shaft and sleeve from wear and scoring.

Automatic adjustment compensates for abnormal shaft-end play, run-out, primary ring wear and equipment tolerances. Uniform spring pressure compensates for axial and radial shaft movement.

Special balancing accommodates higher-pressure applications, greater operating speeds and lower wear.

Non-clogging, single-coil spring allows for greater dependability than multiple spring designs. Will not run foul due to fluid contact.

Low drive torque improves performance and reliability.

Recommended application

For pulp and paper,

petrochemical,

food processing,

wastewater treatment,

chemical processing,

power generation

Operating range

Temperature: -40°C to 205°C/-40°F to 400°F (depending on materials used)

Pressure: 1: up to 29 bar g/425 psig 1B: up to 82 bar g/1200 psig

Speed: See enclosed speed limits chart.

Combination Materials:

Stationary Ring: Ceramic, SIC, SSIC, Carbon, TC

Rotary Ring: Ceramic, SIC, SSIC, Carbon, TC

Secondary Seal: NBR, EPDM, Viton

Spring and Metal Parts: SS304, SS316

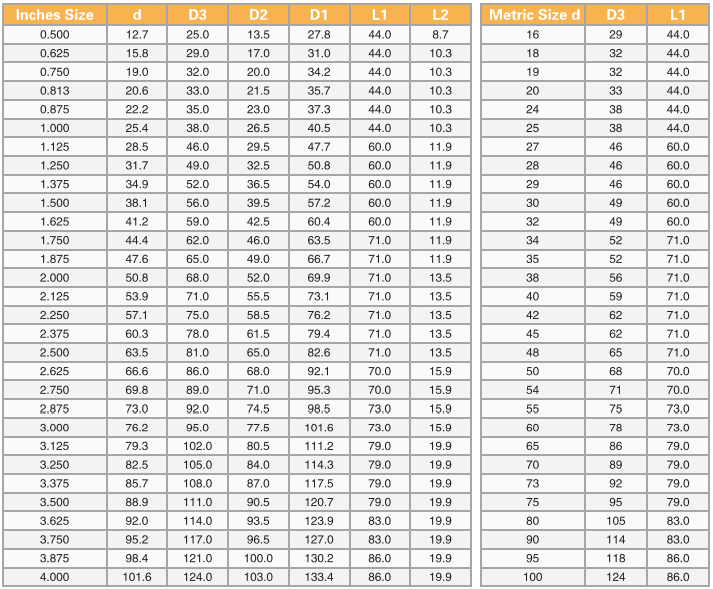

W1A data sheet of dimension(mm)

Our Service

Quality: We have a strict quality control system. All products ordered from our factory are inspected by a professional quality control team.

After-sales service: We provide after-sales service team, all problems and questions will be resolved by our after-sales service team.

MOQ: We accept small orders and mixed orders. According to our customers’ requirements, as a dynamic team, we want to connect with all our customers.

Experience: As a dynamic team, through our more than 20 years of experience in this market, we are still continuing to research and learn more knowledge from customers, hoping that we can become the largest and professional supplier in China in this market business one.

OEM: we can produce customerized products according to customer requirement.

we can produce mechanical seal type 1A with very good price