Replacement for the below mechanical seals

Burgmann M7N ,LIDERING LWS10, Latty U68, Flowserve Europac 600, Vulcan 1677, AESSEAL W07DMU, Anga V, Sterling 270, Hermetica M251.K2

Features

- For plain shafts

- Single seal

- Unbalanced

- Super-Sinus-spring or multiple springs rotating

- Independent of direction of rotation

Advantages

- Universal application opportunities

- Efficient stock keeping due to easily interchangeable faces

- Extended selection of materials

- Insensitive to low solids contents

- Flexibility in torque transmissions

- Self-cleaning effect

- Short installation length possible (G16)

- Pumping screw for media with higher viscosity

Operating Range

Shaft diameter:

d1 = 14 ... 100 mm (0.55 " … 3.94 ")

Pressure:

p1 = 25 bar (363 PSI)

Temperature:

t = -50 °C ... +220 °C

(-58 °F ... +428 °F)

Sliding velocity:

vg = 20 m/s (66 ft/s)

Axial movement:

d1 = up to 25 mm: ±1.0 mm

d1 = 28 up to 63 mm: ±1.5 mm

d1 = from 65 mm: ±2.0 mm

Combination Material

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Cr-Ni-Mo Steel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

Silicone-Rubber(MVQ)

PTFE Coated VITON

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Recommended Applications

- Process industry

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Shipbuilding

- Lube oils

- Low solids content media

- Water / sewage water pumps

- Chemical standard pumps

- Vertical screw pumps

- Gear wheel feed pumps

- Multistage pumps (drive side)

- Circulation of printing colors with viscosity 500 ... 15,000 mm2/s.

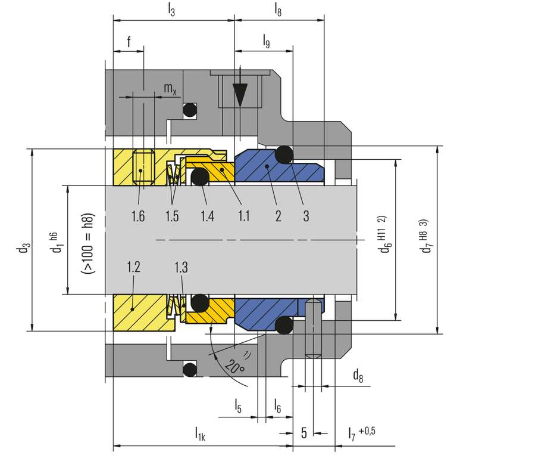

Item Part no. to DIN 24250 Description

1.1 472 Seal face

1.2 412.1 O-Ring

1.3 474 Thrust ring

1.4 478 Righthand spring

1.4 479 Lefthand spring

2 475 Seat (G9)

3 412.2 O-Ring

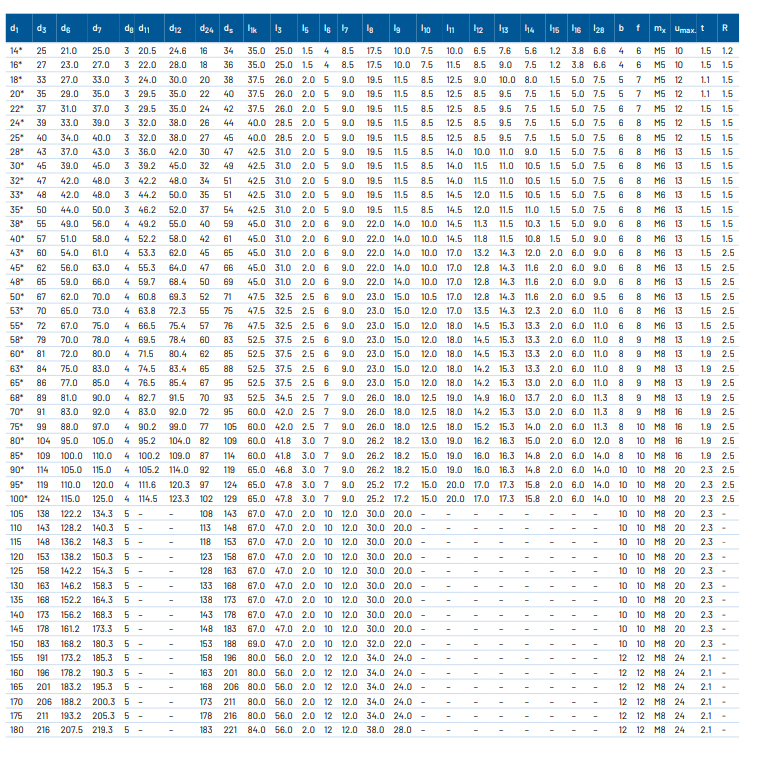

WM7N DATA SHEET OF DIMENSION (mm)